Specifications/Instructions

Specifications

1.0 Performance Requirements

Vertical drainage sheets know as geocomposite drainage board (drainboard) are placed between the back of concrete retaining walls and/or soil nail walls and the retained soil. the drainboard channels water away from the back of the walls to relieve hydro-static pressure that can damage the wall.

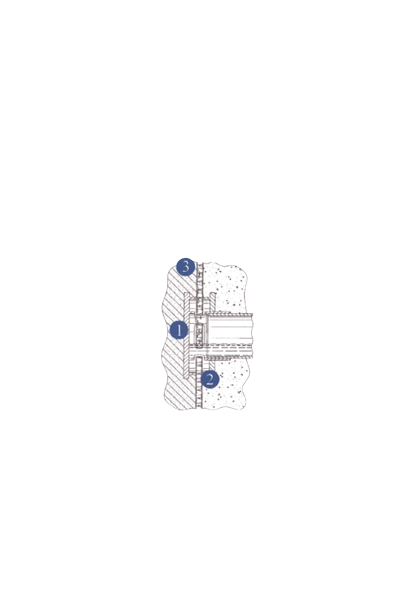

The drainage system shall consist of a drainage collector (1) and a retainer ring (2) that attaches to the drainboard (3) to collect and discharge water that flows into the drainboard. A PVC pipe shall be attached to the drainage collector to carry water through the concrete facing. The drainage collector and retainer shall channel water in the drainboard from an area greater than the diameter of the drainage pipe to increase drainage capacity. The drainage collector and the retainer ring are glued together using All Purpose Cement (suitable for both PVC and ABS plastic). Similarly, the PVC pipe and the drainage collector are glued together with All Purpose Cement.

2.0 Product Material

ABS Plastic (ASTM D4673-02)

3.0 Approved Product

Manufactured by The DrainGreat Company, LLC

Greenville, SC 29615

Installation Instructions

- Form a 4-inch round hole in the geocomposite drainage board (drainboard).

- Insert drainage collector through 4-inch hole from back of drainboard, extending through to front of drainboard.

- Place All-Purpose Cement (suitable for both PVC and ABS plastic) on the portion of drainage collector that extends through drainboard and attach retainer ring. Hand squeese retainer ring to drainage collector to form a seal with drain board until cement sets (about 10 seconds)

- Place All-Purpose Cement on inside of portion of drainage collector that extends through drainboard and attach 3 inch diameter PVC pipe (not included).

Drilling the Hole in the Drainboard

Step-by-Step: Cutting a Drainboard Hole with a Core Bit

To make a hole in drainboard slightly larger than 4 inches, the following method can be used. You will need two boards about 1” x 12”, a hand held drill, and a 4 1/8” diameter bimetal core hole bit.

Use the drill and bit to cut a hole through one of the two boards. In this example, we purchased a Spyder brand bit at Lowe’s

Layer Your Boards Like This for a Clean Cut

Place the board without a hole on the ground (not hard surface as shown, because the core hole bit includes a long drill bit that will penetrate the lower board), place the drainboard on the lower board and then place the board with the predrilled hole on top of the drainboard.

Drill Through the Drainboard Using the Guide

Apply downward pressure to the upper board by standing on it and use the drill to cut through the drainboard, using the upper predrilled hole as a guide. By sandwiching the drainboard between the wood boards, there is less chance of the filter fabric binding up in the core hole blade.

Finish the Cut & Let Us Know How It Goes

Cut just deep enough to penetrate the drainboard and remove the plug of drainboard. We would like your feedback on how this method works for you or any alternative means you come up with for making the hole in the drainboard.